- Home

- Products

- Stop-cut Rollformer / Roll Forming Line

- Light Steel Frame Roll Forming Machine

Light Steel Frame Roll Forming Machine

- We can also offer the FINISHED PRODUCTS for kinds of special profiles according to customers’ drawings, such as:

1. fireproof and heat insulation door and window partition

2. fireproof curtain wall according to customers’ drawings

3. Photovoltaic Solar support

YX Series Light Steel Frame Roll Forming Machine

Name: Light Steel Frame Roll Forming Machine

Model: YX Series

We can also supply the customized machines.

- Features:

Steel framing machine produce galvanized sheet steel or Al-Zn coated steel. The sheets are zinc coated (galvanized) or aluminum-zinc coated to prevent corrosion.

Manufacture of steel framing members adheres to strict tolerances, which results in consistent strength, straightness, and dimensionally stable members.

Steel framing provides excellent design flexibility due to the inherent strength of steel, which allows it to span longer than wood, and also resist wind and earthquake loads.

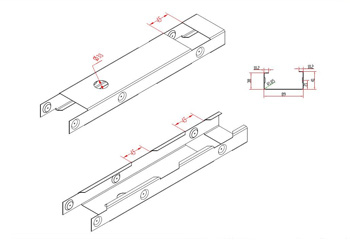

Framing members can be ordered cut-to-length which can result in reduced on site labor costs and reduced on site waste. Framing weighs up to two-thirds less than conventional materials. Lightweight steel framing lends itself to panelization techniques that can speed the on site construction process by allowing the assembly of walls in controlled environments. Steel framing members also have pre-punched holes that allow for easy installation of electrical wiring and plumbing.

Natural disasters, especially earthquakes, are unpredictable in terms of magnitude, frequency, duration, and location. Consequently, the ideal structure to withstand earthquake forces will behave in a consistent and predictable manner. Cold roll formed steel is capable of meeting this standard due to the strict process used to manufacture steel studs, inherent properties of steel and typical construction methods used in steel framing.

The benefits of the steel framing are:

Cost effective; Easy to install; Uniform quality; Strong and lightweight; Design flexibity; Improved construction quality; Fire resistant; Saves labor; Recyclable.

- Applications:

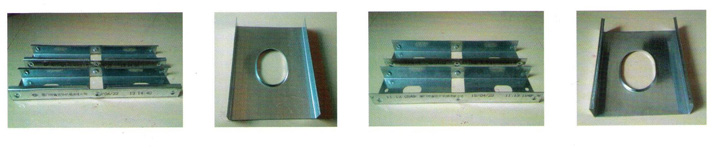

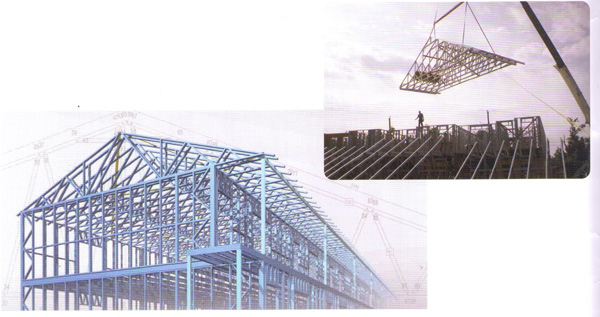

Steel framing utilizes cold roll formed steel members for walls, floors, and/or roofs.

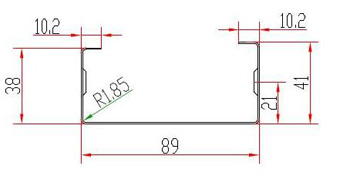

The framing members are C-sections with standard dimensions.

- Process Flow:

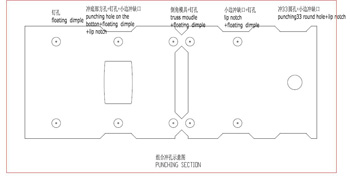

From Coil ---- Entry Guide ---- Punching Die Sets (Dimple, lip cut, notch, truss, service hole, shear) ---- Roll Forming ---- Punching Die Sets (swage) ---- Finished Product

- Machine Configurations:

1. Uncoiler ---- 1 Unit |

2. Feeding and Pre-leveling Device ---- 1 Unit |

3. Hydraulic Punching Device: Dimple, lip cut, notch, truss, service hole, shear, swage ---- 1 Unit |

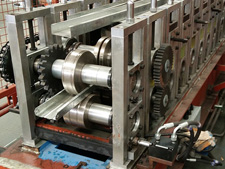

4. Cold Roll Forming Section ---- 1 Unit |

5. CNC Control System ---- 1 Unit |

6. Hydraulic System ---- 1 Unit |

7. Run out Table ---- 1 Unit |

8. Matthews Inkjet Printer ---- 1 Unit |

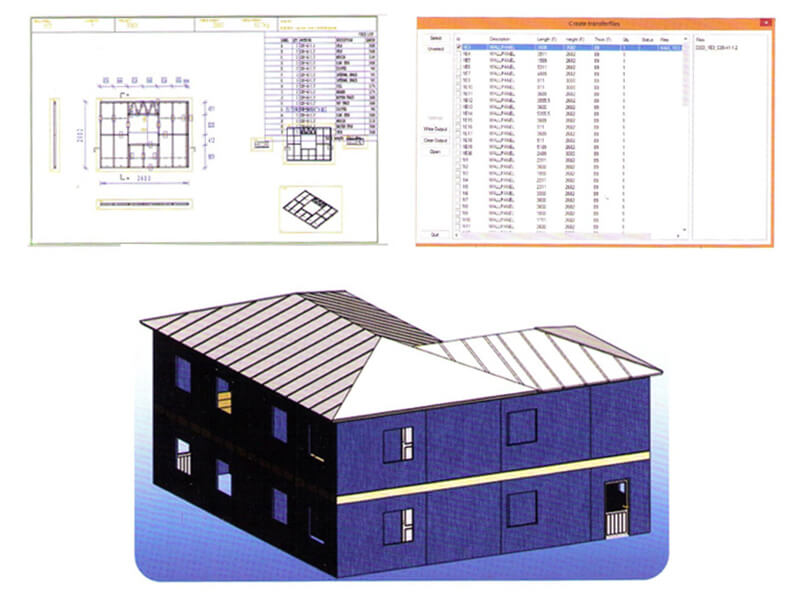

9. Vertex BD Pro Design software ---- 1 License |

- Vertex Software for Light Steel Frame Roll Forming Machine:

- Options for Light Steel Frame Roll Forming Machine:

Single Specification production (1~3 layers construction)

Multi-specification production (1~10 layers construction)

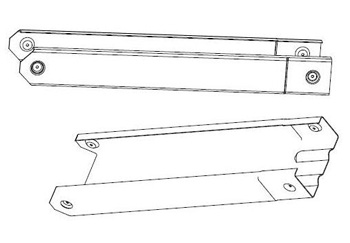

- Profile Drawings for Light Steel Frame Roll Forming Machine:

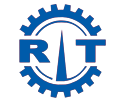

- Photos for Reference:

- Product Tube Mills / Pipe Making Machine Stop-cut Rollformer / Roll Forming Line Fly Cutting Roll Former Line Slitting Lines Cut to Length Lines Auxiliary Equipment

- Contact Us Office Address: No.12, Zhongba RD(S), Hai´an, Nantong, Jiangsu, China Tel: +86 513 889 02466 Mobile/WhatsApp/Wechat: +86 13506296101 Email: offer@reliantt.com

- About Us NANTONG RELIANTT Machinery Co., Ltd. as a member of RLT group, engaged in manufacturing and exporting roll forming machine, tube mills, cut to length line, slitting line, shear and press brake etc for more than 20 years.